How is a Fire Extinguisher Made?

Fire extinguishers are a vital component of your fire safety equipment. They’re dotted around homes and businesses up and down the country, but how much do you know about their history, design and the different types of fire extinguishers?

This month at City Fire Protection, we’ve got a guide for you on how a fire extinguisher is made and all the background you could possibly need on these essential items.

Overview

There is a wide range of fire extinguishers out there, but for this guide, we’re going to be talking about the most common types, specific to the UK. We categorise them by the material they use as each has its own benefits and suitability for different fire types:

- Foam Fire Extinguishers

- Water Fire Extinguishers

- CO2 Fire Extinguishers

- Wet Chemical Fire Extinguishers

- Powder Fire Extinguishers

- Specialist Fire Extinguishers

- — Water Mist

- — Class D

- — Lithium-ion (Aqueous Vermiculite Dispersion)

History of the Fire Extinguisher

Before we get into what fire extinguishers are made of, their design and the different ways they work, let’s take a brief look at how we got to this point.

Ways of extinguishing fires have been around almost as long as fire, from buckets to pumps, humans have always tried to find ways of combating the threat. It wasn’t until 1819, however, that the first portable extinguisher was invented, using potassium carbonate in a copper tank with compressed air pressure.

Other models followed, with some using chemicals which, when mixed, would react to create a foam that could then be discharged – but this, and others like it, required extra steps.

Mid-20th century, we finally got a more modern extinguisher with pressurisation as standard, either with pressurised air or a gas cartridge (more on those later). Different agents have been used to optimise the fight against fires while more recent developments have included automatic extinguishers and self-maintaining units.

To learn more about the different type of fire extinguishers, and their uses, see our guide below:

Fire Extinguishers: The Types and Their UsesMaterials

There are a number of materials that extinguishers are made of, including:

- Aluminium – Used exclusively for CO2 extinguishers due to higher pressure

- Steel – Used for the majority of water and powder-based extinguishers as well as some CO2 units

- Stainless Steel – Used for select extinguisher bodies

- Plastic – Used in the manufacture and assembly of key components

- Rubber – Used in the manufacture and assembly of key components

Design

All fire extinguishers are now designed in a manner that allows them to be put into action swiftly when needed, but that also protects them from being damaged or accidentally discharged.

The British Standard for the performance and characteristics of portable fire extinguishers is BS EN 3-7, something you should be on the lookout for when sourcing your fire extinguishers.

Using pressure – either in the unit itself or an internal cartridge – to discharge extinguishing agents, modern extinguishers have a squeeze (or lever) handle that activates the unit (often using a spring mechanism). This squeeze/lever handle is usually attached directly to the valve assembly but is sometimes positioned in line with the extinguisher hose (most commonly in gas cartridge type extinguishers).

The hose is attached to the extinguisher valve assembly with a nozzle attachment fitted at the end of the hose to control and direct the flow of extinguishing medium during discharge.

Most commonly, a hose is attached to the extinguisher valve assembly – but can be positioned in line with the extinguisher hose – with a nozzle attachment that can be directed at fire. The valve assembly is, in turn, fitted with a discharge dip tube extending from the valve assembly into the sealed extinguisher. This dip tube forms part of the flow path of the extinguisher media from the pressurised body, through the valve, into the hose assembly and through the nozzle attachment to be directed at the base of the fire. More on this below.

Anatomy

We mentioned the development of two different types of modern extinguishers earlier, so let’s take a look in more detail. They are similar in design components for the most part but use different methods to provide the rapid discharging of an extinguishing agent.

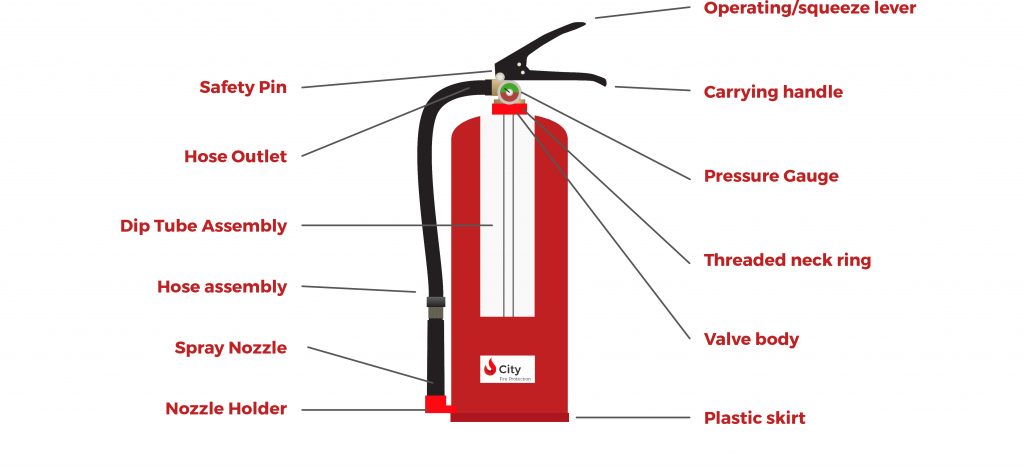

The typical fire extinguisher is made of several parts:

- Extinguisher body

- Operating/squeeze level

- Safety Pin

- Carrying handle

- Hose Outlet

- Pressure Gauge

- Dip Tube Assembly

- Threaded neck ring

- Hose assembly

- Value body

- Spray Nozzle

- Nozzle Holder

- Plastic skirt

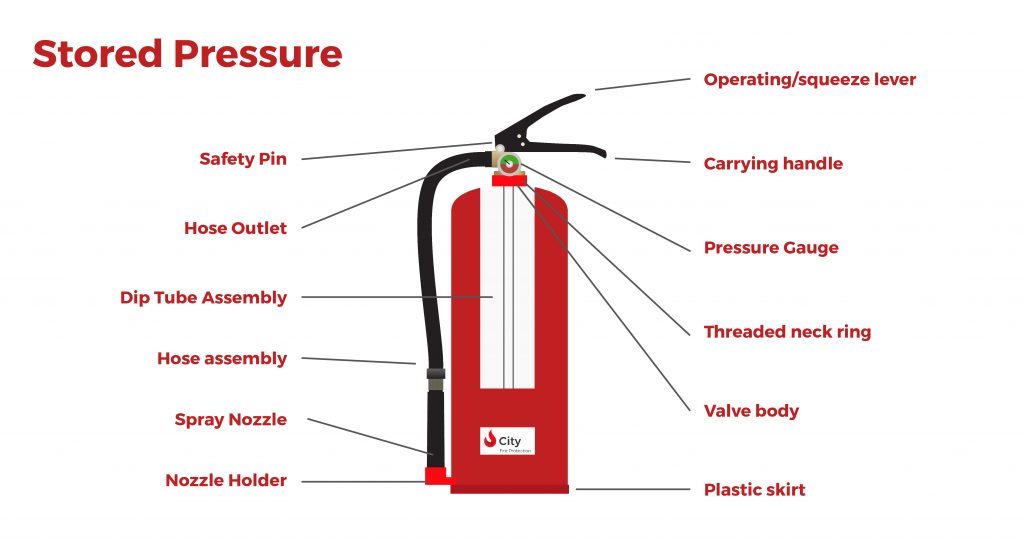

Stored pressure extinguishers

These units are pressurised with a combination of 90% nitrogen and 10% helium via a compressor. The helium is used as a tracer gas during the leak detection process, helping ensure the unit is properly sealed against a loss of pressure.

When you squeeze the handle of the extinguisher, the pressure difference between the internal and atmospheric pressure is what causes the content to be discharged, along with the pressuring gas itself. It’s important to note that once used, no matter how much volume of gas or media has been discharged, your extinguisher should be sent away for recharging or refilling. CO2 extinguishers are stored pressure extinguishers where the pressurising gas is also the extinguishing agent.

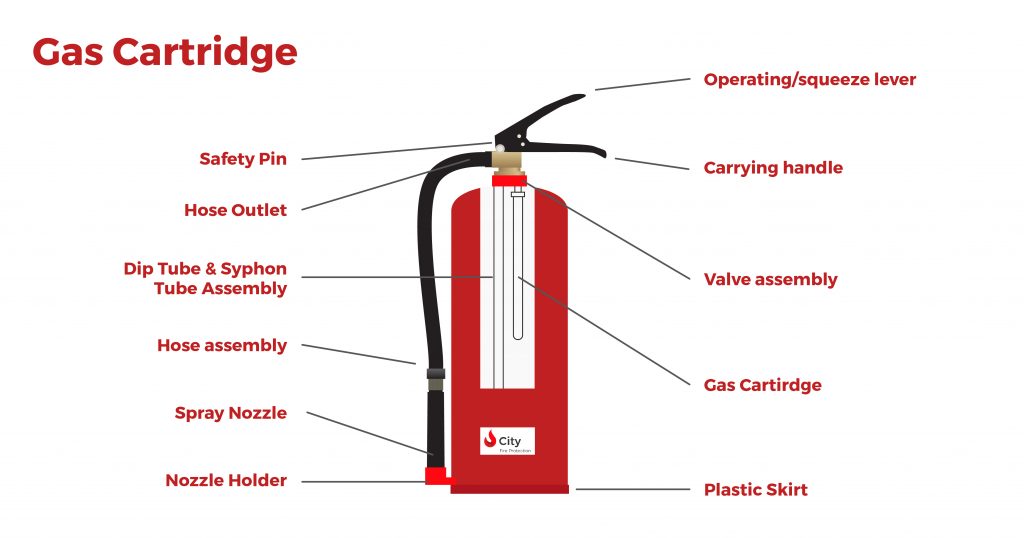

Gas cartridge extinguishers

While similar in design, this type of extinguisher uses a CO2 or nitrogen cartridge which is pierced when the handle is squeezed. The pressure of the expanding gas is what then forces the extinguisher agent to be discharged via the dip tube.

Most extinguishers use the stored pressure type, with dry powder sometimes paired with the gas cartridge to better preserve the agent inside from damp air or contamination.

Unlike stored pressure extinguishers, gas cartridge extinguishers are only pressurised on activation with the breaking of the cartridge seal. This means they are less likely to leak over time as they only become pressurised at the point of activation.

Manufacturing Process

As you can probably imagine, with the range of extinguisher types available, the manufacturing process can also vary.

Extinguisher Bodies

It’s usually CO2 extinguishers that are made slightly differently, with the bodies made from aluminium as a “seamless” unit – all one component to be more secure in holding 55 bar of pressure on average. A process known as cold impact extrusion is used where a hydraulic ram is used to press and form an aluminium slug into a hollow shell, before going through a heat treatment process to increase strength.

Water and powder-based extinguishers, on the other hand, are made out of mild steel in a process known as deep drawing. This is where the cylinder body is deep drawn and the base and the dome of the extinguisher are formed separately, then welded to the cylinder body.

Valves

Typically made from brass, the shape of valves is created in a process called forging – a hot metal-forming process using brass bar stock. After forging, the valve bodies are then machined to create openings and threads.

There are some valve bodies that can be made out of aluminium, stainless steel or plastic, but these are much rarer, with brass remaining the most widely used material.

Dip tube

These tubes are usually made out of plastic or aluminium.

Nozzles

This portion can be made from brass, aluminium or even plastic.

Labelling

The front label/marking on an extinguisher contains important safety and operating instructions. BS EN 3-7 strictly controls this labelling or marking of a portable fire extinguisher. Each and every fire extinguisher, therefore, is required to be marked with:

- The charge of the filled extinguisher (e.g. 2L, 2Kg, 6L, 9Kg etc.)

- The fire rating that the extinguisher achieved during testing (e.g. 13A, 89B, etc.)

- Pictograms showing the method of operation, with simple written instructions

- Pictograms showing the fire types the extinguisher is suitable for us on (e.g. A, B, C, etc.)

- A colour-coded band on the label that corresponds to the extinguisher media type (e.g. cream for foam, red for water, black for CO2, etc.)

- The contact details of the extinguisher manufacturer and/or supplier

Our labelling is clearly colour coded, and also includes simple instructions on how to use the fire extinguisher.

Testing and Quality Control

There is a lot of testing and quality control that goes into manufacturing fire extinguishers, both in terms of our own manufacturing as well as for the suppliers of different components.

Testing and quality control in our factory is conducted to BS EN 3-7 and includes:

- Burst testing (to match suppliers’ results)

- Visual inspection of cylinders and valves (for corrosion, weld defects and paint coating defects)

- Discharge testing

- — Duration of discharge

- — Residual content after discharge

- Analysis of pressuring gas

- Leak detection (in a sealed chamber)

After this, 5% of all finished product is then inspected for a final quality check. Each of our extinguishers has a barcode attached to the unit and against this barcode, batch information for all the raw components used in manufacture are attached. This gives full traceability of each quality critical component throughout the entire supply chain.

All our extinguishers are approved to BS EN3-7 through BSI’s Kitemark scheme and we hold PED & MED approvals with our nominated body Apragaz.

Supplier of our components will need to provide a variety of quality and testing documents, including:

- Raw material testing

- Declarations of Conformity for the cylinders and valves to state that they comply with PED/Pressure Equipment (Safety) Regulations 2016

- Evidence of BS EN 3-7 testing

- Burst testing of cylinders and valves

- Testing of paint coating (to check it adheres to the metal correctly)

- Testing of the internal polythene lining (water-based units)

Extinguisher products for sale in the EU market have to comply with the Pressure Equipment Directive (PED) and must be CE marked. For sale in the UK market, products must comply with the Pressure Equipment (Safety) Regulations 2016 from 01/01/2023 and be UKCA marked. CE marking is recognised until this date. This is because extinguishers are classed as pressure vessels, requiring strict standards to ensure safety.

Supply and Installation

At City Fire Protection, we supply and install a full range of fire extinguisher types for businesses across London, Birmingham and throughout the UK. Selection and siting of extinguishers is carried out in line with BS 5306-8, while commissioning and maintenance is conducted to BS 5306-3. This is made possible with the backing of our parent group LS Fire Group and our sister brands.

All our extinguishers are manufactured at our UK-based factory in Elland, West Yorkshire, assuring you of high-quality units to help you safeguard your staff, building and assets regardless of the sector or industry you operate in. From schools and educational facilities to warehouses and factories, our expert team can cover all your fire extinguisher requirements.

Call our team today on 0800 9981 908 if you need brand new fire extinguishers or replacements for your business.

Send us a message